Hologic Costa Rica Earns Zero Waste Pre-Certification

When it comes to sustainability at Hologic, the Costa Rica site has pioneered many environmental initiatives. It was the first site to implement solar energy and utilize water reclamation systems to offset consumption. They now lead the company in a new way: zero waste pre-certification.

The journey began back in 2020 with a waste audit. Several types of problematic waste were identified that required a better disposal strategy, including multiple plastic types, wood, electronics, mixed materials, metal chips, hazardous materials, batteries, used machinery oil, food leftovers, empty food containers, empty printer toner, used clean room suits and shoe covers, nitrile and neoprene gloves, and damaged or unused equipment and furniture. The sheer length of this list of waste types illustrates just how complicated it can be to deal with trash.

However, site leaders were motivated to change and began the application process for Total Resource Use and Efficiency (TRUE) zero waste certification. The pre-certification stage recognizes projects that have implemented the fundamental actions and policies needed to effectively pursue zero waste and have demonstrated a commitment to achieving TRUE certification, a globally recognized standard for green business practices. This incremental pathway to TRUE certification prioritizes the core actions essential to getting a successful start toward zero waste.

Once the troublesome waste streams were identified, suitable disposable options needed to be found. All items were split into two streams: eco-friendly and compliance options. A compliance option refers to approved mechanisms for waste handling, such as chemical recycling or waste-to-energy options. A final treatment process was negotiated with a Costa Rica Healthcare Ministry-authorized supplier. That supplier provides a waste treatment certification every month.

Quote from Nilo Caravaca

“We’re very proud of the work we’ve done. Not only have we been able to grow, adding more manufacturing capabilities, more services and a record-high number of employees, but we’ve also made year-over-year progress in environmental sustainability.”

Peter Templeton, President and CEO of Green Business Certification Inc., praised Hologic's progress, “This accomplishment confirms that you have visibly embraced the goal of zero waste and future TRUE certification. More importantly, you have demonstrated your leadership by taking action toward those goals.”

Hologic’s employees can request raw material packaging waste -- for example, pallets, wood boxes, cardboard and plastics. They rebuild it into furniture, fences, doors, walls and DIY projects. Currently, about 45 employees request the materials a month, transforming about 100 tons of would-be waste annually. Unused waste is sent to different companies where it can be reused as raw material in their processes.

Since 2020, Hologic has also participated in the Dona Tapa Project. This initiative belongs to the Costa Rican Accessible Tourism Network, aiming to make Costa Rican beaches accessible to all people with any kind of disability or reduced mobility so they can enjoy the sand and the sea. This Project consists of recollecting Class 2, 4 and 5 polymer plastic and then recycling them to create plastic wood. These materials are used to create specialized items, such as retractile runways, which provide easier transit for wheelchairs on the sand. The ultimate objective is for Costa Rica to be the first country in Central America with beaches fully accessible to the disabled.

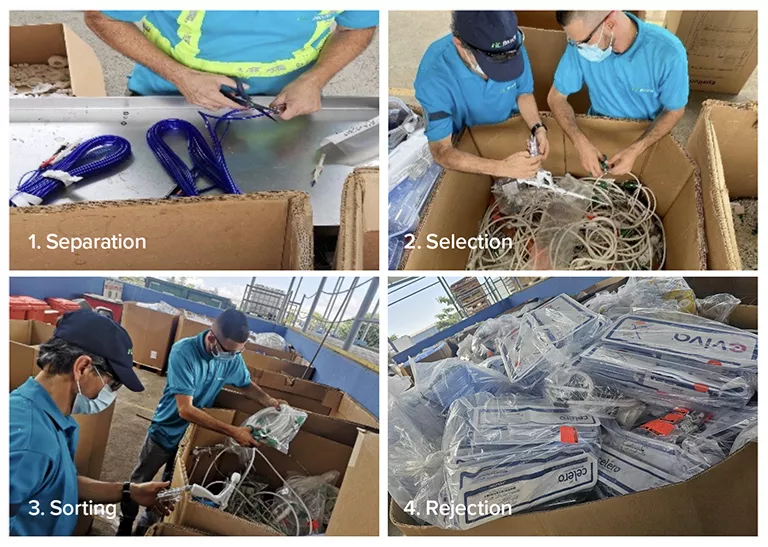

Prior to Hologic's fiscal year 2021, all rejected units manufactured were sent to an external supplier for disposal. The eco-friendly waste treatment team defined a sustainable alternative, so these units are now pulled apart in an on-site waste management center, and their various components are split into recyclable pieces. Before this project implementation, a shipping container full of rejected units was permanently parked in a warehouse loading dock. From a recycling rate standpoint, this methodology allowed between 60% and 90% eco-friendly treatment.

The site also partnered with a cafeteria supplier to define a procedure for transforming organic waste into compost through an organization certified by the Costa Rican Ministry of Agriculture and Livestock. About 1.2 tons of organic waste are treated as compost every month. The supplier arrives at the site every day, picks up the food leftovers, and transports them to a compost farm.

Nilo Caravaca noted, "We're committed to these efforts, pouring our time and energy into making Hologic Costa Rica an even more sustainable place to work."